8:00 - 17:30

Monday to Saturday

Monday to Saturday

Thermal Control

By rapidly drawing heat from critical components, the aluminum core lowers operating temperatures. This superior thermal management protects devices and extends their lifespan, especially in demanding, high-power environments.

High Current

With exceptional thermal conductivity, aluminum PCBs handle higher continuous currents than FR-4 boards without the risk of overheating. This makes them the ideal choice for robust power electronics and LED drivers.

Stability

Because aluminum’s thermal expansion rate closely matches that of copper, it minimizes stress on solder joints during temperature changes. This results in highly stable and reliable performance across a wide operational range.

Compact Design

The aluminum base acts as an integrated heat sink, often eliminating the need for a separate component. This smart integration reduces product weight, enables more compact designs, and lowers overall assembly costs.

Construction and Application of Aluminum PCBs

An Aluminum PCB (also known as an aluminum substrate or MCPCB) consists of a copper circuit layer bonded to a thermally conductive insulator, which is then mounted on a solid aluminum base. This structure excels at spreading and dissipating heat, making it essential for LED lighting, power converters, automotive electronics, and other applications where thermal management is critical. The aluminum base also provides robust mechanical strength, allowing it to replace fragile and expensive ceramic substrates in many high-power designs.

Aluminum PCBs support all standard surface finishes. For cost-sensitive projects, finishes like OSP or HASL provide excellent solderability without the expense of maximum shelf life or corrosion resistance. Conversely, for designs demanding superior surface planarity and oxidation resistance, premium finishes such as ENIG are the ideal choice.

At PCBAIR, we handle all aluminum PCB fabrication in-house, offering a range of customizable options. You can specify key parameters like aluminum core thickness, dielectric thermal conductivity (from 1 to 9 W/m·K), and copper weight. We then engineer the board to your precise specifications. Our commitment to quality is absolute: every board undergoes 100% electrical testing (E-test) and AOI inspection before shipment, guaranteeing performance and reliability you can trust.

Aluminum PCB Manufacturing Process & Techniques

1. Design, Materials, and Engineering

Reliable manufacturing is essential for performance in high-power applications. We begin with premium materials, selecting high-grade, aluminum-core laminates and thermally conductive dielectrics. Our engineering team collaborates with you upfront to optimize the PCB stack-up, copper weight, and design rules—such as ensuring proper insulation spacing from the metal core—before production begins.

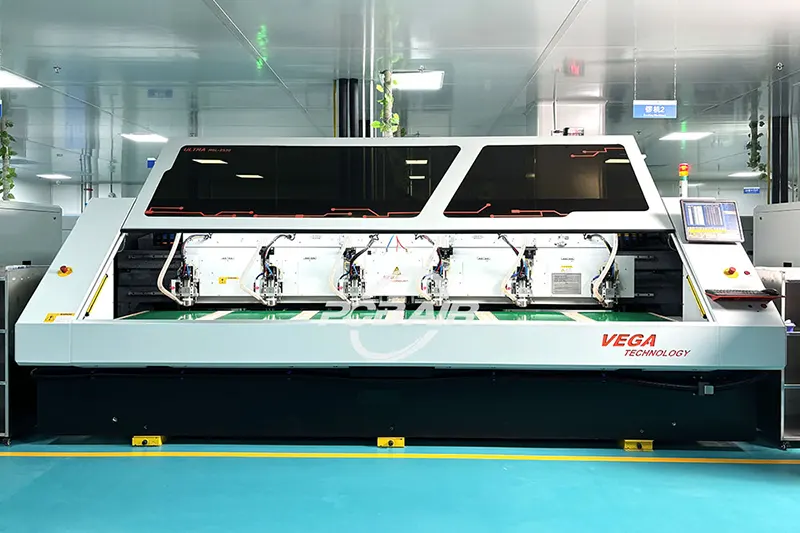

2. Precision Fabrication and Drilling

We use computer-controlled CNC machinery for high-precision drilling and routing to create exact hole placements and board outlines. For certain features like mounting holes, punch presses are also utilized, as they can be more effective than drilling through the solid metal base.

3. Deburring and Edge Finishing

A critical step for aluminum PCBs is meticulous edge and hole finishing. Removing any metal burrs is vital for two key reasons:

- Preventing Short Circuits: Eliminates the risk of sharp metal slivers causing electrical shorts.

- Ensuring Safe Assembly: Provides smooth, safe-to-handle edges for a seamless fit in your final product.

4. Specialized Surface Preparation

Unlike standard FR-4, aluminum requires a specialized chemical pre-treatment. This process creates a thin, insulated oxide layer on the aluminum surface, which is essential for achieving robust bonding and reliable electrical insulation for the subsequent circuit layers.

5. Controlled Circuit Etching

Only after the surface is prepared do we apply photoresist and image the circuitry. The copper etching process is carefully controlled with specialized etchants. These chemicals are formulated to cleanly define the copper traces without attacking or compromising the integrity of the underlying aluminum core.

6. Solder Mask and Specialty Finishes

After etching, the board is cleaned and solder mask is applied and cured. For many applications, specialty masks are used:

- High-Reflectivity White: Often used for LED boards, this mask can maximize light output by 85% or more.

- Standard Colors: Green, black, and other colors are available for all other applications.

7. Surface Plating Options

To protect the exposed copper pads from oxidation and ensure excellent solderability, we apply a final surface finish. We can precisely control the plating thickness to meet all IPC standards, with options including:

- Lead-Free HASL

- ENIG (Immersion Gold)

- Immersion Silver

- OSP (Organic Solderability Preservatives)

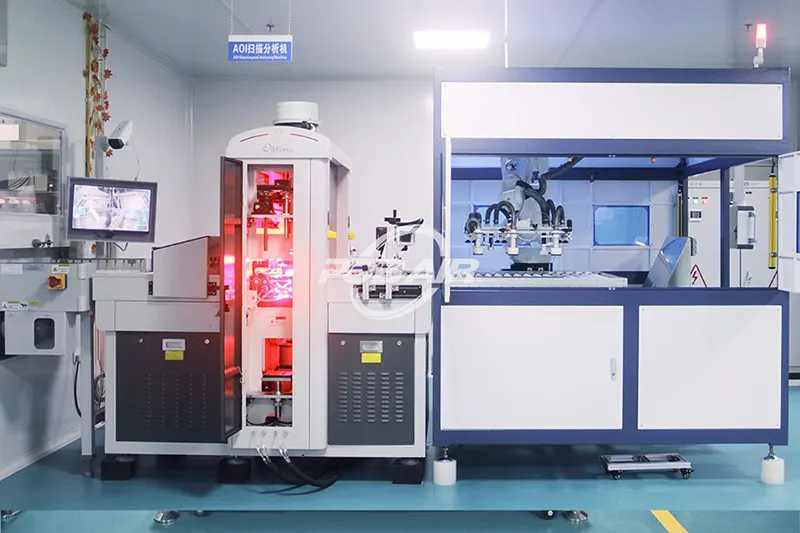

8. In-Process and Final Testing

Rigorous quality control is enforced at every stage. We use AOI after critical steps to catch any trace or spacing defects. Finally, every board undergoes thorough electrical testing to verify connectivity and performance, ensuring it can handle the intended power and dissipate heat effectively.

This stage-by-stage commitment to quality means the finished aluminum PCBs will meet the high-performance standards our customers demand.

Why Choose Us as Your Aluminum PCB Manufacturing Partner?

PCBAIR is a leading PCB manufacturer in China. We produce a range of metal-core boards from single-sided to complex 6-layer constructions, accommodating both prototype and large-volume production orders. All fabrication is performed to meet strict industry standards, such as IPC and UL certifications. With over a decade of experience, our engineering team offers Design for Manufacturability (DFM) feedback to help customers optimize their designs for cost and efficiency. Key manufacturing processes are handled in-house, which provides direct control over production quality, scheduling, and cost.

Competitive Pricing

With over 10 years in the PCB industry, PCBAIR has established a reliable supply chain that ensures access to premium components at competitive prices. For complex projects needing special materials or advanced technical specifications, our strong manufacturing capabilities enable us to provide cost-effective solutions while maintaining high quality.

Fast and Reliable Delivery

We ensure rapid production times, with samples shipped within 24-48 hours and mass production orders delivered within 72-120 hours. Our partnerships with global logistics providers like UPS, EMS, FedEx, DHL, and TNT guarantee prompt and reliable shipping, supported by our digitalized factory management and 90% automation for enhanced efficiency.

Quality Assurance

Our rigorous quality inspection begins with incoming material checks. We use AOI to detect defects and X-ray to identify internal issues. Electrical performance testing is performed with advanced automatic test machines and flying probe testers. Before shipment, our dedicated QC team conducts a thorough manual visual inspection to ensure all products meet strict quality standards.

Customer Service

Our experienced sales, order management, and engineering teams provide expert support throughout your project. The sales team handles support and project follow-ups, while the order management team ensures timely quotations and monitors production status. Our engineering team reviews your design files, offering professional advice to optimize production efficiency.

PCB Laminate Materials Suppliers

To ensure your PCBs are reliable and perform well, we use high-quality laminate materials. We have built strong partnerships with top suppliers in the industry, including trusted brands like Rogers, Panasonic, Dupont, Arlon, Taconic, Nelco, Isola, Teflon, and more. This means you receive the best materials tailored to your project needs, providing the performance and durability you expect.

Aluminum PCB Capabilities

By reviewing the following aluminum PCB capabilities table, you can briefly understand what we can do.

| Specification | Capability |

|---|---|

| Base Material | Aluminum (1060 3003,5052,6061), Copper Core |

| Thermal Conductivity | 1.0 -9.0 W/m·K (Standard and High Thermal Performance Dielectrics) |

| Layer Count | 1-2 Layers (Single & Double Sided), up to 4 Layers for complex designs |

| Mixed stackup | FR-4+aluminum substrate FR-4+copper substrate |

| Board Thickness | 0.5mm – 5.0mm |

| Aluminum Core Thickness | 0.4mm, 0.6mm, 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm, 3.2mm |

| Maximum Copper Thickness | 6 OZ (Inner & Outer Layers) |

| Dielectric Thickness | 75µm, 100µm, 125µm, 150µm (0.003″, 0.004″, 0.005″, 0.006″) |

| Maximum PCB Size | 610 x 1200mm |

| Breakdown Voltage | >3000V AC |

| Finished Surface | HASL (Lead-Free), ENIG, ENEPIG, Immersion Silver, OSP |

| Solder Mask | White (High Reflectivity for LEDs), Black, Red, Green, Blue |

| Special Process | V-CUT/Scoring, Countersinks, Beveled Edges, Direct Thermal Path (DTP) |

Need Help With Your Project?

Please send us a message, and our aluminum PCB manufacturing capabilities can help you complete your next project.

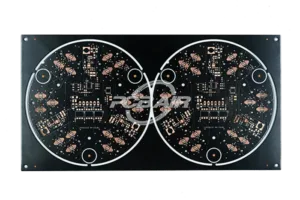

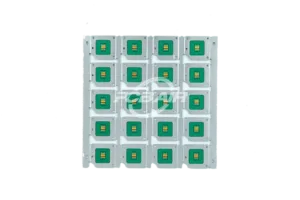

Aluminum PCB Samples We Manufacture for Our Customers

Our manufacturing capabilities are validated by internationally recognized certifications, demonstrating our ability to meet the stringent requirements of diverse industries. We hold key credentials including ISO 9001 for quality management and IATF 16949 for automotive standards. Furthermore, our products are UL certified for safety and fully compliant with RoHS and REACH environmental regulations. Beyond standard inspections, we conduct reliability tests like thermal stress testing to verify long-term performance. This comprehensive system ensures every board we deliver, like the aluminum PCB samples shown below, meets exacting standards of quality and reliability.

Aluminum PCB Manufacturing Equipment

Our 65,000 sqft production campus is equipped with advanced fabrication machinery. Our CNC drilling and routing machines ensure precise hole placement and board dimensions on aluminum substrates, maintaining tight tolerances from prototypes to large production batches. We utilize high-speed automated plating lines to apply copper and surface finishes with high uniformity, which is critical for excellent conductivity across all traces and pads.

We also employ specialized equipment to handle the unique demands of metal-core manufacturing. This includes dedicated machinery for precise deburring and edge finishing, such as creating beveled edges or countersinks required for mechanical mounting. For advanced inspection, our facility is also equipped with X-ray systems to verify structural integrity, ensuring every PCB is built to specification.